When you’re considering gearboxes, it’s crucial to look beyond just the initial purchase price. You’ll find that maintenance costs, operational efficiency, and the potential impact of downtime significantly affect your bottom line. Investing in a high-quality gearbox might strain your budget at first, but the long-term savings and improved performance could make it worthwhile. As you weigh these factors, it’s important to understand the broader implications for your operations. What might you uncover about the true cost of ownership?

Initial Purchase Costs

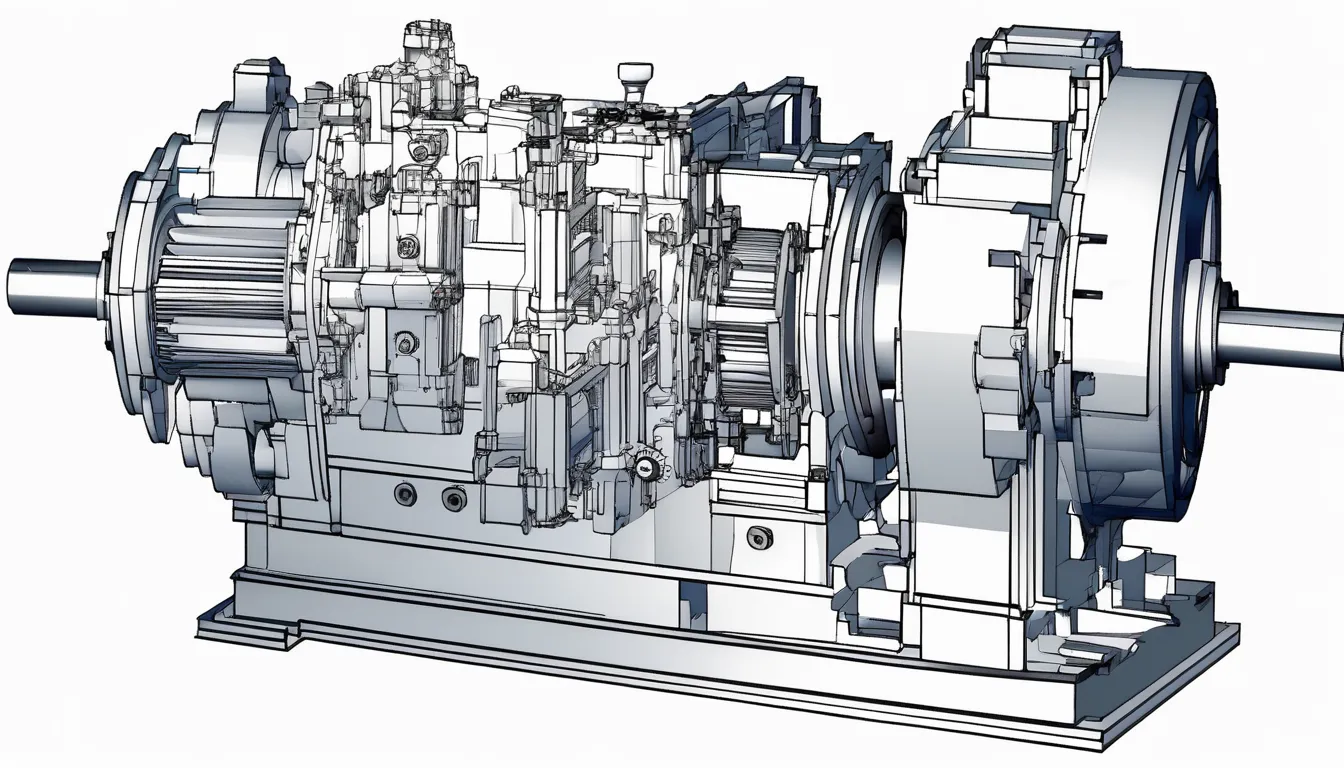

When you’re considering the initial purchase costs of a gearbox, it’s essential to factor in not just the price tag, but also the specific requirements of your application. Different applications demand different gearboxes, and their prices can vary significantly.

For example, high-performance gearboxes designed for heavy-duty tasks typically cost more due to their durability and advanced engineering.

You should also consider the gearbox type that suits your needs. Helical, bevel, and worm gearboxes each have unique advantages and pricing structures.

Additionally, the size and capacity of the gearbox will impact the cost. Larger gearboxes often come with a heftier price tag, reflecting their ability to handle greater loads.

Don’t forget about the material used in the gearbox construction. Using high-quality materials can increase the gearbox’s initial cost, but it may lead to better efficiency and longevity in the long run.

Lastly, consider any customization or additional features you might need, as these can quickly increase your overall expenditure.

Maintenance and Repair Expenses

Maintenance and repair expenses are crucial factors to consider when evaluating the total cost of owning a gearbox. You need to account for these costs to ensure your investment remains viable over time.

Regular maintenance can prevent unexpected breakdowns and extend the lifespan of your gearbox, but it does come with its own set of expenses.

Here are some key considerations regarding maintenance and repair costs:

- Routine Inspections: Regular checks can identify potential issues before they escalate.

- Lubrication Costs: Keeping gears well-lubricated reduces wear and tear, but requires ongoing expense.

- Replacement Parts: Over time, components may need to be replaced due to wear, affecting your budget.

- Labor Costs: Hiring skilled technicians for maintenance or repairs can add up quickly.

- Downtime Expenses: If your gearbox fails, the cost of lost productivity can be significant.

Operational Efficiency and Savings

Investing in a gearbox involves more than just maintenance and repair expenses; it also significantly impacts operational efficiency and overall savings. A well-chosen gearbox optimizes your machinery’s performance, allowing for smoother operation and reduced energy consumption. This efficiency translates directly into cost savings, as less energy means lower utility bills.

When you select the right gearbox, you enhance the productivity of your equipment. Improved torque transmission and reduced friction lead to quicker production cycles, which can boost your output without the need for additional resources. You’ll notice that your operational costs decrease as you streamline processes and minimize waste.

Moreover, an efficient gearbox often requires fewer repairs and less frequent replacements, which further contributes to your bottom line. By minimizing downtime and ensuring consistent performance, you can allocate resources more effectively and focus on growth opportunities.

In the long run, investing in a high-quality gearbox pays off. You’re not just cutting costs; you’re investing in sustainability and reliability, which benefits your operation’s financial health.

Impact of Downtime

Downtime can cost businesses thousands of dollars, making it crucial to understand its impact on operations. When a gearbox fails, the repercussions can ripple through your entire organization, affecting not just production but also your bottom line.

You need to recognize that each hour your machinery is offline translates into lost revenue and increased expenses.

Consider these key impacts of downtime:

- Lost Productivity: Every minute counts; unplanned downtime halts production, affecting your output rates.

- Increased Labor Costs: Your workforce may need to work overtime or even hire temporary staff to catch up once operations resume.

- Repair Expenses: Beyond the immediate cost of repairs, you’ll also face expenses related to sourcing replacement parts.

- Customer Dissatisfaction: Delays can lead to missed deadlines, damaging relationships with clients and harming your reputation.

- Opportunity Costs: While you’re dealing with downtime, competitors may seize the opportunity to capture your market share.

Long-term Investment Considerations

When evaluating the financial implications of your industrial gearbox manufacturer , it’s essential to consider long-term investments that can enhance efficiency and reliability. Investing in quality components, regular maintenance, and advanced technology can significantly reduce operational costs over time. You’ll want to focus on aspects that provide a solid return on investment and lead to improved performance.

To help you visualize some key considerations, here’s a simple table:

| Investment Type | Benefit | Considerations |

|---|---|---|

| Quality Components | Longer lifespan | Higher initial cost |

| Regular Maintenance | Reduced breakdowns | Scheduled downtime needed |

| Advanced Technology | Improved efficiency | Training may be required |

Conclusion

In conclusion, grasping the financial aspects of gearboxes is crucial for making informed decisions. While high-quality gearboxes might seem expensive at first, their durability and efficiency can lead to substantial savings over time. By considering maintenance costs and the impact of downtime, you’ll see that investing in reliable gearboxes pays off in the long run. Ultimately, prioritizing quality not only enhances machinery performance but also supports your bottom line and sustainability goals.